About Us

Awesome! ZS Gasoline Engine is Produced on Intelligent Assembly Line

Everybody knows that even the small gasoline engine also contains more than 120 components. Within 10 seconds, however, one perfect product can be assembled and sent end off line with qualified quality in ZS Power Factory. Then how to make it in such a short of time? With this question, please allow me to introduce our ZS Power production line. Today, I am going to take you to see our miraculous A1 line, which is one of the eights lines at ZS General Machine. Why I say it is miraculous? Because in every 10 seconds, there is a finished product flow out of line and its FTQ is 99.3%, which leaves nothing more to be desired.

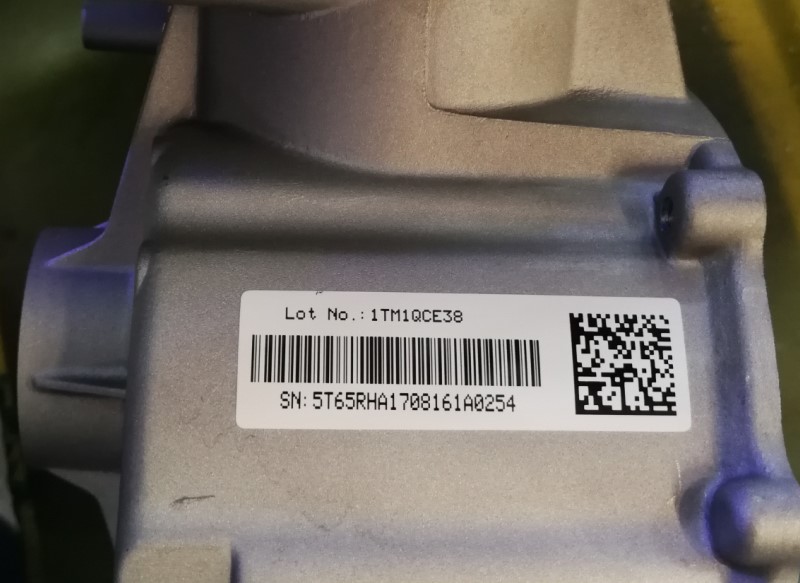

Miraculous A1 line It is due to the intelligent “Brian” -- Central Servers, after consulted with the team leader of the A1 Line, we learned that this intelligent network formed an interconnection between human to machine and machine to machine which then achieved highly integrated horizontally and vertically. Then with curiosity, I walked through the whole production line. First station of the line is identity input station, which is to engraving the unique serial number and sticking the barcodes on each product.

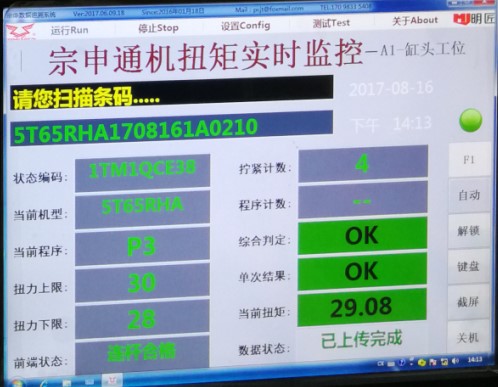

In production, each station must do data collection and inspection via sensor, and then upload the data to “ Cloud System” so as to recording and saving all the information on each process from parts online to packaging, and those data can be accessed, reviewed at any time. The product can flow into next station only when those data of the product is qualified, which is truly implement the poka-yoke in process, and ensure the high efficiency and high quality of the production and products fundamentally.

Except these constantly monitoring equipment and automation equipment, A1 Line also makes me pleasantly surprised. Flywheel tightening station has a machine to tighten flywheel nuts automatically, whether vertical or horizontal engines, the machine can judge it and use both sides of automatic torque gun to tighten it into place. This machine can maintained the consistency of the torque in assembling while controlling the assembly pace of the production at the same time, which efficiently enhances the production quality.

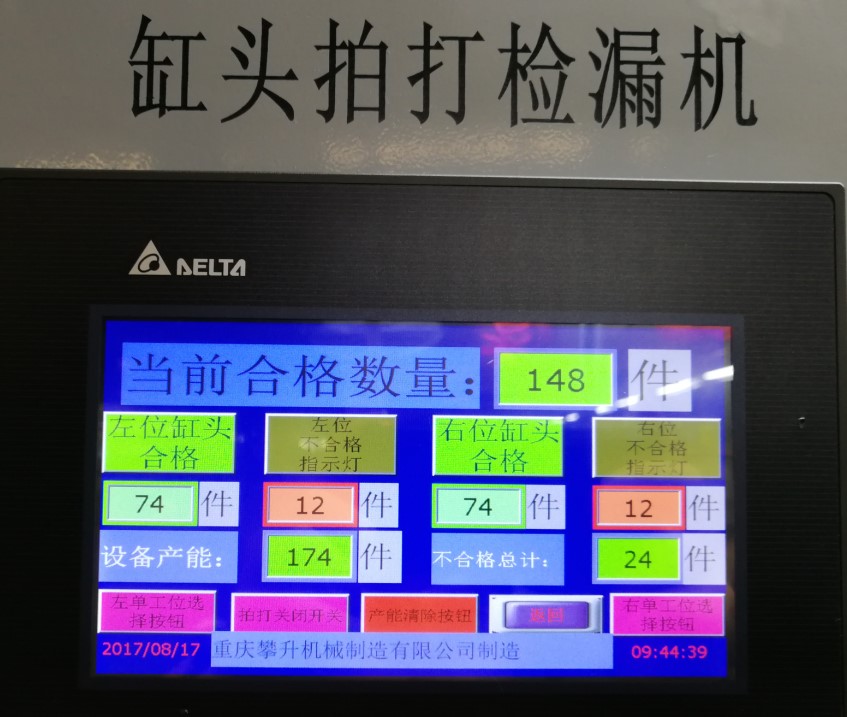

There are eight more “Flexible” stations, like flywheel tightening station, operated by auto equipment and more flexible than ever before. And the team leader of the A1 line also told me that gradually there will be more “flexible” auto assembly stations with transforming and upgrading of the line. Cylinder head leakage check station, the gadget of the test machine pushes the cylinder head to check its air leakgae

100% performance test on engine

Full auto packaging process

A1 Line is just one of the eight production lines in ZS Power Factory, there are more to be explored. Right now, ZS Power has achieved production intelligence and automation by information technology and reduced the manual interference successfully, which made production process more efficient and under controlled, and meanwhile, collect the data more accuracy and timely and arrange the production plan and monitor the production progress more reasonably. Within the one to two years, ZS Power is going to constantly upgrading its production lines based on the concepts of “Green, Intelligent and Efficient” and aim to build a high efficiency, energy saving, green, environment friendly and comfortable humanized factory. Let’s do look forward to! |